Screw machining and ecology: an alliance for a green future

Screw machining is a technique for manufacturing metal parts used in many industries, including automotive, aerospace and electronics. Although this technique is essential to produce precision components, it has long been associated with environmental concerns due to the quantity of raw materials used and the waste generated.

However, in recent years, the screw-machining industry has made significant progress in reducing its impact on the environment.

Here are some of the measures taken to promote ecology in the screw-machining sector:

– Use of sustainable materials: Screw machining companies are increasingly adopting sustainable materials, such as recycled aluminium, to reduce their carbon footprint. Replacing steel with lightweight, recycled aluminium alloys reduces the weight of components, resulting in lower fuel consumption and reduced greenhouse gas emissions.

– Waste reduction: Screw-machining processes have been optimised to minimise waste. Modern machines are able to produce parts more accurately, reducing the need for rework or rejection of faulty components. In addition, metal chips generated during screw-machining are collected and recycled rather than discarded, reducing the amount of wasted material.

– Energy savings: Screw-machining companies are investing in modern, energy-efficient screw-machining equipment. Innovations such as energy recovery during the cutting process and the use of variable frequency drives to adjust machine speed according to requirements are helping to reduce energy consumption and cut greenhouse gas emissions.

– Recycling: Obsolete or faulty parts are often recycled to recover materials. This reduces the demand for virgin raw materials while minimising waste.

– Water and chemical management: Screw-machining companies prefer to use water-based lubricants and cutting fluids rather than harmful chemicals. This approach aims to reduce the impact on aquatic ecosystems. They set up wastewater management systems to limit residues of harmful substances in the environment.

– Appropriate filtration systems: Companies use appropriate filters to eliminate particles, oil mist and other pollutants from the air.

– Awareness-raising: Companies in the sector make their employees aware of the importance of environmentally friendly practices. Training in waste management, energy saving, and carbon footprint reduction has become commonplace.

– Working with production partners: SadevTEQ works with its production partners to ensure that the materials and components they use meet high environmental standards. This collaboration can go as far as encouraging production partners to adopt sustainable practices.

Screw machining, although once seen as a wasteful and wasteful industry, is moving towards more environmentally friendly practices. Technological advances, changes in materials and environmental awareness are helping to make screw machining a greener sector, helping to combat climate change and promote a sustainable future.

Read more news

Screw Machining for curious little ones, explained to a 7-year-old

Screw Machining for curious little ones, explained to a 7-year-old: when magic transforms metal !A brief history of screw-cutting: In the Middle Ages, in the age of knights, a special kind of magic was born in the village of Saint-Sigismond in Haute-Savoie, thanks to...

Your frequently asked questions !

Your frequently asked questions !Optimise your production with SadevTEQ: A trusted partner for your machined parts Machined parts play a crucial role in many industries, from aerospace and hydraulics to locksmithing and electronics. When you're looking for a reliable...

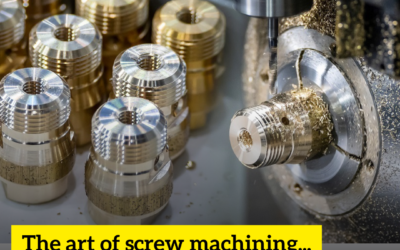

The Art of Screw machining: When Precision Becomes Crucial with SadevTEQ

The Art of Screw machining: When Precision Becomes Crucial with SadevTEQScrew machining is a technique for manufacturing mechanical parts where precision is paramount. It is essential to the manufacture of components for a variety of industries including aerospace,...