Your frequently asked questions !

Optimise your production with SadevTEQ: A trusted partner for your machined parts

Machined parts play a crucial role in many industries, from aerospace and hydraulics to locksmithing and electronics. When you’re looking for a reliable partner to meet your machined parts needs, SadevTEQ stands out for its commitment to quality, its range of materials and its diversified processing capabilities. We answer all your questions about screw machining.

What are the diameters of the parts?

SadevTEQ stands out for its ability to meet a wide range of dimensional requirements. Whether you need parts with a diameter of 0.5 mm for delicate electronic components or parts with larger diameters up to 80 mm for more robust applications, our dimensional flexibility guarantees tailor-made solutions for all projects. We understand that dimensional accuracy is crucial to the smooth operation of your systems, and we are committed to supplying parts that meet the highest standards.

What materials are machined?

Materials play an essential role in the performance of machined parts. SadevTEQ offers a complete range of materials, including brass, copper, steel, plastic, stainless steel, aluminium and bronze. This variety of choice ensures optimum adaptability to your specific needs.

Do you take care of treatment?

SadevTEQ ensures that its subcontractors carry out surface and heat treatments to increase the durability, strength and efficiency of your parts. From zinc plating to gold plating, polishing, passivation and tefloning, our treatment options are designed to meet a variety of requirements.

Are you certified?

SadevTEQ’s ISO 9001:2015 and NF EN 9120:2018 certifications attest to our commitment to operational excellence and consistent product quality. We are committed to the highest standards, ensuring our customers have complete confidence in our processes. In addition, to maintain a high level of quality and reliability, we regularly audit our partners.

Do you check the parts?

Our commitment to quality does not end with certification. Our quality department carefully checks and inspects the parts, ensuring that they fully comply with your specifications.

Where are your production units located?

With production units mainly located in Europe, SadevTEQ offers its customers an advantageous geographical proximity. This facilitates communication, reduces delivery times and reinforces our commitment to exceptional customer service.

What sectors of activity are you active in?

SadevTEQ operates in a variety of sectors, including hydraulics, aeronautics, electronics, connectors & cables, fasteners and electricity. Our versatile experience enables us to understand the specific needs of each sector and provide solutions tailored to each application.

What kind of machinery do you have?

Thanks to close collaboration with trusted partners, we can guarantee efficient production, and give our customers access to a dense and diversified machine park that can adapt to a wide variety of part types. What’s more, we go beyond simply supplying parts, offering storage solutions and reduced delivery times, thereby helping to optimise your supply chain.

SadevTEQ is a strategic partner, ready to meet your most demanding machined parts requirements. Our commitment to quality, range of materials, advanced processing capabilities and global presence make us the ideal choice for your projects. Contact us today!

Read more news

Screw Machining for curious little ones, explained to a 7-year-old

Screw Machining for curious little ones, explained to a 7-year-old: when magic transforms metal !A brief history of screw-cutting: In the Middle Ages, in the age of knights, a special kind of magic was born in the village of Saint-Sigismond in Haute-Savoie, thanks to...

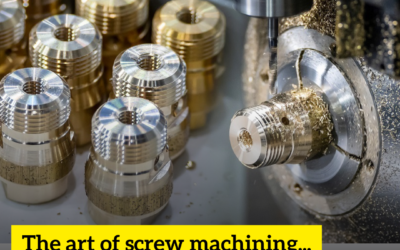

The Art of Screw machining: When Precision Becomes Crucial with SadevTEQ

The Art of Screw machining: When Precision Becomes Crucial with SadevTEQScrew machining is a technique for manufacturing mechanical parts where precision is paramount. It is essential to the manufacture of components for a variety of industries including aerospace,...

Screw machining and ecology: an alliance for a green future

Screw machining and ecology: an alliance for a green futureScrew machining is a technique for manufacturing metal parts used in many industries, including automotive, aerospace and electronics. Although this technique is essential to produce precision components, it...